Introduction to 4 Ton Steam Boilers

Steam boilers are an essential component in a wide range of industrial operations, providing the necessary steam for heating, power generation, and various processing tasks. A 4 ton steam boiler refers to the boiler's capacity to produce four tons of steam per hour. This category of boiler is a common choice for industries due to its balance between steam output and footprint.

Types and Applications

The 4 ton boiler comes in various types, including fire tube, water tube, and combination boilers, each suitable for specific applications. Fire tube boilers are simpler in design and are commonly used for small to medium steam or heating requirements. Water tube boilers, on the other hand, are ideal for high-pressure applications. The boiler 4 ton capacity is versatile, catering to industries such as food processing, textile, chemical manufacturing, and more.

Features and Materials

A 4 ton steam boiler is designed with efficiency and durability in mind. Common materials used in their construction include steel and cast iron, which provide longevity and resistance to high temperatures and pressures. The design often incorporates features such as economizers and superheaters to enhance efficiency and performance.

Advantages of a 4 Ton Boiler

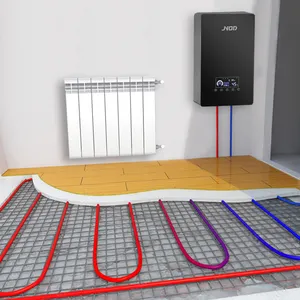

The advantages of a 4 ton boiler are numerous. Its capacity to produce a substantial amount of steam makes it a valuable asset for large-scale operations. The efficiency of a 4 ton steam boiler is a significant benefit, as it ensures that more heat is transferred from the fuel to the water, reducing energy consumption. Additionally, the even heating distribution characteristic of steam boilers ensures a comfortable environment when used for heating purposes.

Energy Efficiency and Cost Savings

Energy efficiency is a critical aspect of a 4 ton steam boiler. With advancements in technology, these boilers are designed to minimize heat loss, ensuring that most of the energy is used in steam production. This efficiency translates into cost savings for businesses, as less fuel is required to produce the desired amount of steam.

Selecting the Right 4 Ton Steam Boiler

When selecting a thermax 4 ton boiler, it is crucial to consider factors such as the type of fuel it will use, the available space for installation, and the specific requirements of the process it will serve. While the thermax 4 ton boiler price is an important consideration, it should be weighed alongside the boiler's operational efficiency and compatibility with the intended application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4