Introduction to 1200 Ton Injection Molding Machines

Injection molding machines are pivotal in manufacturing, enabling the production of a vast array of plastic components. The 1200 ton injection molding machine stands as a robust example of this technology, designed to meet the substantial demands of large-scale production. These machines are engineered to mold plastic materials into desired shapes with precision and efficiency.

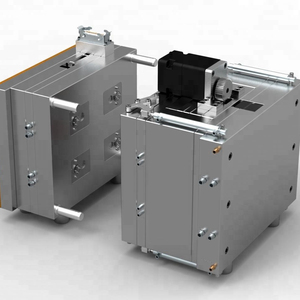

Technical Specifications and Features

A 1200 ton injection molding machine is characterized by its clamping force of 1200 tons, capable of resisting significant external machining forces. The specialized screw design enhances plasticizing shot weight and speed, ensuring consistent product quality. The single-cylinder system with a servo-valve is central to its operation, providing a reliable and responsive molding process.

Applications and Versatility

The versatility of the 1200 ton injection molding machine is evident in its wide range of applications. From creating thin-wall containers for the packaging industry to producing intricate PVC pipe fittings, these machines have the adaptability to serve various sectors, including consumer electronics, pharmaceuticals, and the automotive industry.

Design and Durability

Durability is a hallmark of the 1200 ton injection molding machine, with a design that minimizes wear resistance. The steel bush in the clamping unit is structured to reduce lubrication effects, potentially lowering operational costs. The robust construction of these machines promises a long service life, making them a reliable choice for plastic processing businesses.

Efficiency and Precision

Efficiency is paramount in injection molding, and the 1200 ton injection molding machine is optimized for high-speed operations without compromising precision. The precise control mechanisms ensure improved accuracy in product dimensions, catering to businesses that prioritize both speed and quality in their manufacturing processes.

Environmental Considerations

Modern 1200 ton injection molding machines are designed with environmental considerations in mind. The efficient use of plastic granules and the reduction in lubrication oil usage contribute to more sustainable production practices, aligning with the growing emphasis on eco-friendly manufacturing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4