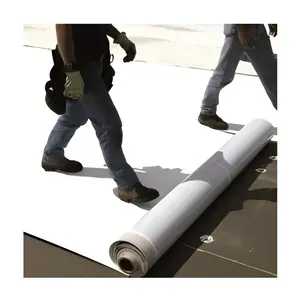

PVC roofing is renowned for its impressive strength, contributing to its longevity as a roofing material. Its robustness is evidenced by its ability to exceed the American Society of Testing and Materials' (ASTM) minimum requirement for weight-bearing capacity, handling significantly more than the standard 200 lbs per square inch. This characteristic is a testament to its durability, making it a reliable choice for long-term roofing solutions.

The durability of PVC roofing is further enhanced by its unique hot air welded seams. These seams create a watertight bond that is stronger than the PVC material itself, ensuring a high level of resistance to moisture. Unlike other materials that rely on adhesives or tapes, the welded seams of PVC roofing provide a superior seal that contributes to its overall resilience and longevity.

PVC roofing also boasts a resistance to a variety of environmental factors. It is highly resistant to chemical exposure, making it suitable for buildings in industrial settings where contact with harsh substances is common. Additionally, its fire-resistant properties add a layer of safety, as it does not support combustion and can help extinguish flames once the source is removed. The material's ability to withstand strong winds, including those experienced during Category 3 hurricanes, further underscores its suitability for areas prone to extreme weather conditions.

Moreover, PVC roofing's resistance to water is particularly notable. The material's design allows it to remain watertight even in the harshest of storms, and it can withstand conditions such as ponding water and varying alkaline levels. Its resistance to mold, bacteria, and plant roots is an added advantage, contributing to a lower need for maintenance and repairs over its lifespan.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4