DIY Round Rectangle Square Heart Star Shape Key Ring/Bottle Opener/Fridge Magnet Pin Button Badge Making Machine

50mm Square Shape Magnet Machine Kit, machine, cutter, and 100 sets materials

Global best seller photo magnet machine Various types and sizes photo magnet making machine

50*50MM 80*53MM Manual Rectangle Fridge Magnet Maker Machine All-Metal Tinplate Badge Making Machine With Mold

Courage Wholesale Manual Round Square Pin School Mirror Button Metal Fridge Magnet Press Badge Making Machine Without Mould

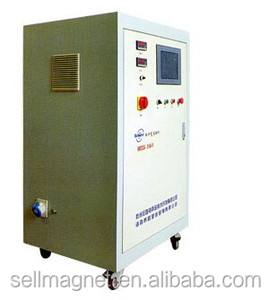

Dexinmag Industrial Magnetizer Machine Demagnetizer Machine Magnet Charger Demagnetization Machine for Motor Magnet and Speaker

Hot Sales 63.5*63.5mm Manual Fridge Magnet Making Machine

VAT2020 Low Power Speaker Magnetizer Magnet Charger Magnetizing Machine

50mm Square Shape Magnet Machine Kit, machine, cutter, and 100 sets materials

Manual Fridge Magnet Making Machine,Machine For Fridge Magnet,Magnet Button Making Machine

80*53mm china online custom paper magnet fridge magnet making machine

Magnetizer machine for magnet magnetization

Pneumatic badge button pin making machine size 72x42x60cm metal pin badge button magnet making machine

Manual Rectangle Fridge Magnet Maker Machine Fridge Magnet Making Machine

China Wholesale Custom Pin Badge Maker Manual Making Magnet Button Badge Machine

Factory price fridge magnet making machine

80*100cm Large Format Clamshell Heat press machine Having magnetism Automatic lifting high pressure sublimation transfer machine

HAOQI Brand china manufacturers magnet round magnet charger machine 12 inch speaker neodymium magnet

Preferential automatic 3D PVC fridge magnet making machine

Super N50 Disc 5mm x 2mm Neodymium Small Mini Custom Automatic Fridge Magnet Machine

motor magnetic free energy magnetic generator magnet making machine

automatic magnet machine magnet pressing machine

Advanced Technology Good Price Ferrite Magnetizer Machine

Automatic Magnet and Iron Sheet Plate Pasting Machine Box Iron And Magnet Pasting Gluing Machine

RubySub Electronic Magnet Sublimation Hat Heat Press Machine For Custom Hats

ab Desktop Automatic Glue Dispensing and Magnets Assembly Automatic Machine Model331 dispenser machine

warp knitting spare parts karl mayer RJSC jacquard machine L magnet

automatic 3D PVC fridge magnet making machine

Professional Supply Magnetizer Machine For Magnetizing N35 D8mm And 3mm Thickness Magnets

Automatic pvc cup mats/fridge magnet making machine

Good quality neodymium magnet for magnet separator machine

DAIXI MD40 Magnet bench drill machine for metal Manual type mini bench electric magnetic drill machine

souvenir custom resin PVC fridge magnet making machine and 3d metal refrigerator magnet photo frames

China Strong Permanent Fridge Magnet Making Machine for Sale

Electronic Magnet Sublimation Hat Heat Press Machine For Custom Hats

Manual Fridge Magnet Machine photo magnet machine badge making machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4